Condition Monitoring for Early Fault Detection

Equipment reliability is a top concern for manufacturers, distributors, utilities, and many other businesses. Failures and unexpected downtime not only impact productivity and maintenance costs; if product or service delivery is interrupted, valuable customer relationships could also suffer damage. Fortunately, modern technology enables a variety of businesses to continuously monitor the condition of vital equipment, helping ensure smooth, predictable, and safe operations.

Why is condition monitoring important?

Condition monitoring has become a critical practice in several industries for fault detection, enabling employees to address equipment faults and failures before they require costly maintenance or result in unplanned downtime. Condition monitoring is a systematic process of collecting and analyzing equipment data to make ongoing assessments of equipment health and performance. With this insight, businesses can enhance equipment reliability and reduce unplanned downtime.

How can businesses optimize equipment reliability?

In recent years, smart infrared technology has taken condition monitoring and predictive maintenance to the next level. By combining infrared technology with artificial intelligence and machine learning, MultiSensor AI helps businesses optimize their equipment maintenance strategies. This cutting-edge approach to infrared technology offers significant advantages over traditional methods.

How does MSAI Connect work?

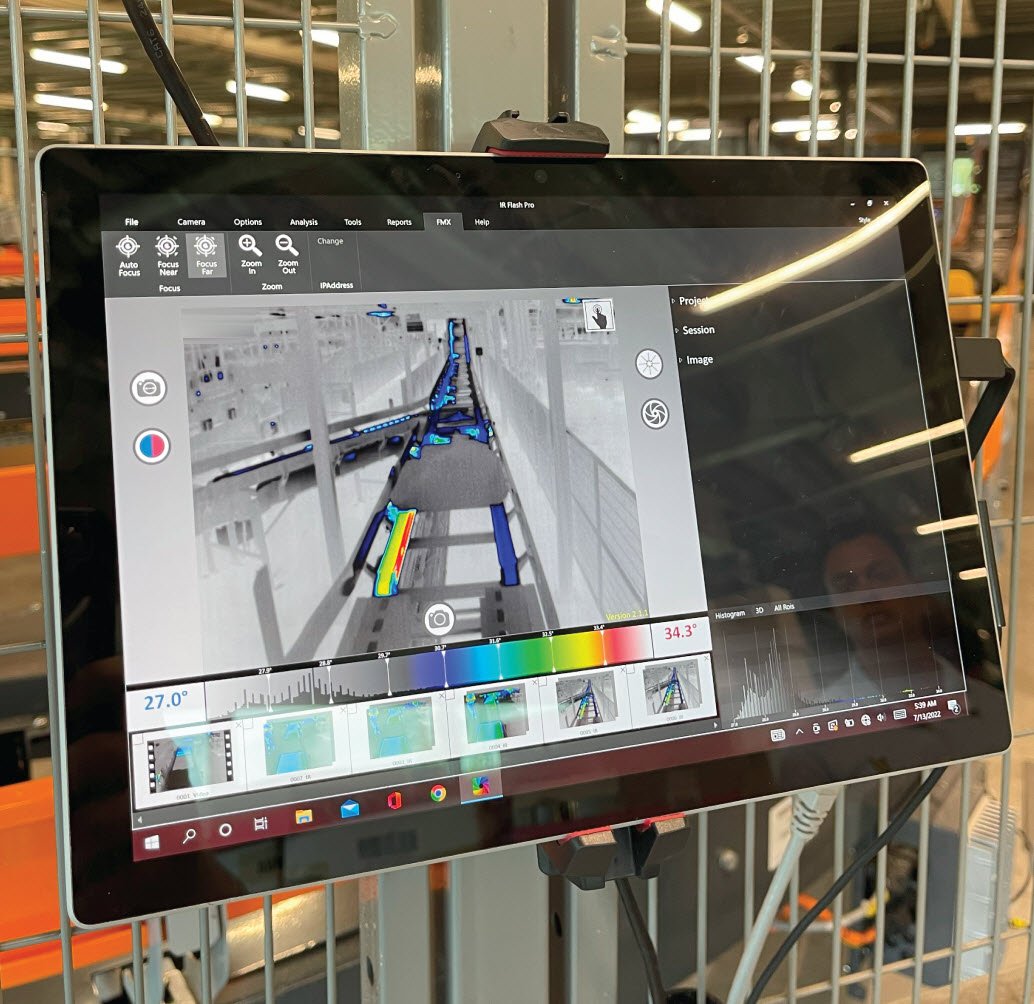

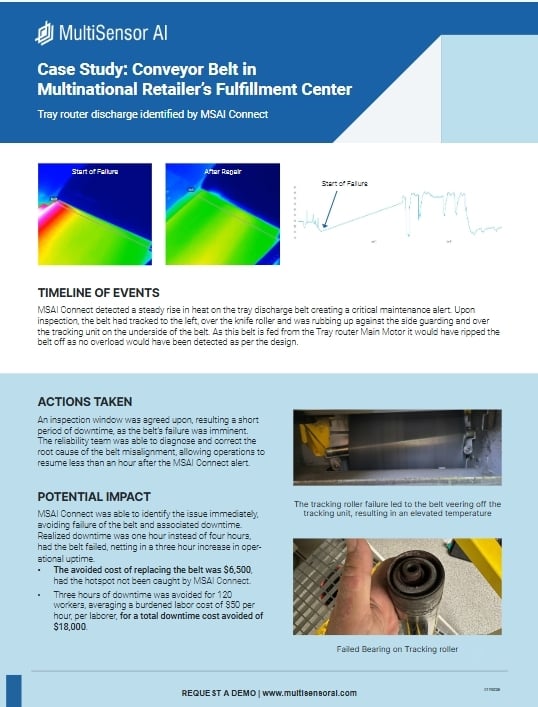

Infrared sensors provide precise monitoring of the temperature of electrical and mechanical assets, such as motors, tanks, and conveyors. When temperature readings deviate from a device’s normal operating range, the MSAI Connect platform automatically alerts key personnel to the issue in real time. Alerted employees can create work orders within the app, allowing them to address the problem remotely for quick resolution, preventing further damage or loss.

This has the potential to save tremendous amounts of time and money over relying on periodic inspections, which can miss many issues that aren’t easily detectable. Additionally, inspectors often lack the data needed to make historical comparisons. MSAI Connect's AI and machine learning capabilities analyze a continuous stream of data to enable ongoing optimization of predictive maintenance and materials sourcing.

How do businesses use MSAI Connect?

MSAI Connect is used in a range of business settings to enhance equipment reliability, design strategic maintenance plans, and increase safety. Below are some examples of how the technology can support a variety of industries.

Manufacturing

MSAI Connect helps manufacturers not only monitor equipment and schedule predictive maintenance but also manage quality control and safety risks. Early detection of anomalies can provide opportunities to improve productivity, enhance energy efficiency, prevent unnecessary downtime, implement safety measures, and maintain high product quality. For example, MultiSensor AI’s proprietary algorithms can identify temperature anomalies and sequential changes in motors to streamline predictive maintenance and optimize motor performance in conveyance systems, pumps, compressors, and other manufacturing machinery.

Warehousing & Distribution

Warehouses and distribution centers rely on a variety of complex assets, such as gearboxes, motors, conveyors, and electrical components, to support critical operations. When these essential items aren’t working properly, businesses can experience efficiency losses, costly maintenance and downtime, and safety hazards. Smart thermal imaging technology enables employees to visualize these assets in real time or via recordings and receive immediate alerts when anomalies are detected. This provides valuable opportunities for warehouses and distributors to increase efficiency, conduct predictive maintenance, and take appropriate safety measures to prevent accidents.

Energy

In electric facilities and substations, thermal imaging provides continuous monitoring for power equipment and other critical assets. Using non-contact temperature measurement, it can detect hotspots and electrical faults to enhance safety, equipment reliability, and efficiency. In oil and gas facilities, infrared technology monitors tanks and flares and allows real-time or recorded viewing of oil wells. Optical gas imaging allows operators to visualize otherwise invisible gasses, allowing early leak detection without the need to put personnel in harm’s way. When these technologies are combined with the power of AI software, companies in the energy industry can optimize their maintenance and safety protocols to reduce costs and protect workers, the public, and the environment.

How does MSAI Connect help businesses succeed?

A proprietary platform leveraging AI and thermal data monitoring, MSAI Connect is easy to implement. Experts from MultiSensor AI help business leaders identify appropriate targets for monitoring and then set up cameras and alert protocols. Immediately upon implementation, users gain access to real-time visibility of monitored assets, recorded video, and automatic alerts.

In an increasingly competitive business environment, companies across industries face a pressing need to optimize operations. AI-supported condition monitoring empowers a wide variety of businesses to streamline maintenance schedules, prevent downtime, and enhance workplace safety. The benefits of real-time actionable insights into the performance of critical assets resound throughout an organization, affecting costs, revenues, and relationships with employees, customers, and the public.

To learn more about AI-powered thermal insights with MSAI Connect, request a demo here.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.