Gain a Competitive Edge with a Data-Driven Maintenance Strategy

As a business leader, you want to protect your organization from liabilities while optimizing productivity and profitability. Keeping machinery running smoothly, safely, and efficiently with preventive maintenance is an important part of supporting these objectives. An effective, proactive maintenance program has many benefits. It cuts costs and minimizes downtime while extending equipment life and improving energy efficiency, customer satisfaction, and environmental sustainability. Implementing cutting-edge smart technology enables you to go a step beyond by creating a predictive maintenance routine that relies on real-time insights to help you pinpoint what maintenance tasks need to be done and when. In this article, we’ll explore how predictive maintenance can help you protect your assets and keep your operation running smoothly.

The Importance of Preventive Maintenance

In its most basic form, preventive maintenance relies on regular checkups to ensure machinery is running within defined parameters and prevent premature failure. This allows businesses to avoid the costs and downtime that arise when machinery breaks down. However, because this kind of preventive maintenance is performed on a set schedule, it can miss problems that arise between scheduled maintenance tasks. On the other hand, it also requires technicians to work on machines that are working perfectly well, undermining operational efficiency. Despite these drawbacks, preventive maintenance saves substantial time, money, and other resources compared to a break/fix model.

Smart Technology and Predictive Maintenance

Predictive maintenance is a strategy that uses real-time information about asset condition to schedule maintenance tasks. Remote monitoring combined with machine learning and artificial intelligence technologies can make this process seamless, analyzing data to provide moment-by-moment insight into equipment condition and performance. This data-driven approach enables businesses to avoid unnecessary maintenance while better ensuring continuous equipment availability and extending machinery life. A predictive maintenance program has several advantages over a traditional preventive maintenance plan.

More Efficient Maintenance Planning

Predictive maintenance allows for more effective resource planning. It avoids the dangers of fixing equipment only after it breaks as well as the unnecessary costs of regularly scheduled maintenance. Performing maintenance tasks only when needed can save money on parts, labor, and planned downtime, and real-time visibility into the condition and performance of your machinery lets you make maintenance decisions with confidence.

Less Unplanned Downtime

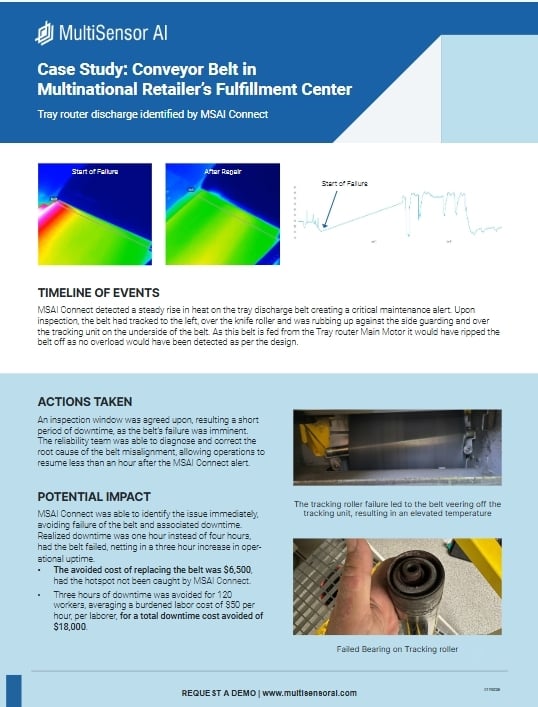

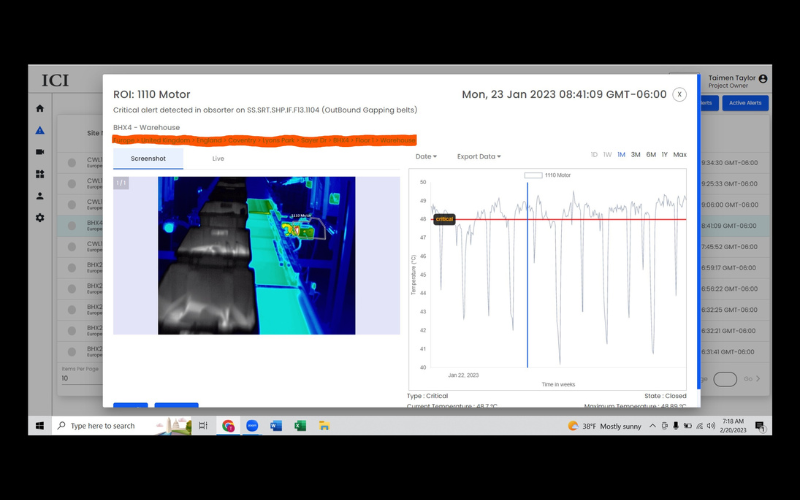

Often, AI-powered insights into equipment performance can predict problems before issues become apparent to human observers. With the enhanced vigilance this smart technology offers, you’re better equipped to prevent breakdowns that interrupt operations and waste labor hours. Maintenance can be scheduled before equipment breaks, at times that are least disruptive to your business.

Longer Equipment Life

When you have continuous information about how your equipment is operating, you gain the power to resolve issues before they threaten the health and longevity of your machinery. An immediate heads up about anomalies in equipment performance allows you to take the best possible care of your assets so they last longer. By avoiding the need to replace machinery prematurely, an AI-enabled predictive maintenance system could quickly deliver a positive ROI.

Improved Safety

Business is about more than profits; it’s also about people. Your employees and your community trust you to operate your business safely. You can honor that trust and protect the people who make it possible for you to do business by identifying and addressing potential hazards promptly. A predictive maintenance program that integrates modern smart technologies can alert your team as soon as equipment deviates from defined parameters, giving them precious time to mitigate risks and prevent harm to people as well as property and shared natural resources.

Enhanced Sustainability

When you reduce waste and improve safety in your operation, you lighten its environmental footprint. As awareness of environmental perils grows, the public is increasingly holding companies accountable for their impacts. To survive and thrive into the future, businesses must become part of the solution. Predictive maintenance allows you to prevent environmental damage while also supporting your company’s bottom line.

MSAI Connect for Predictive Maintenance

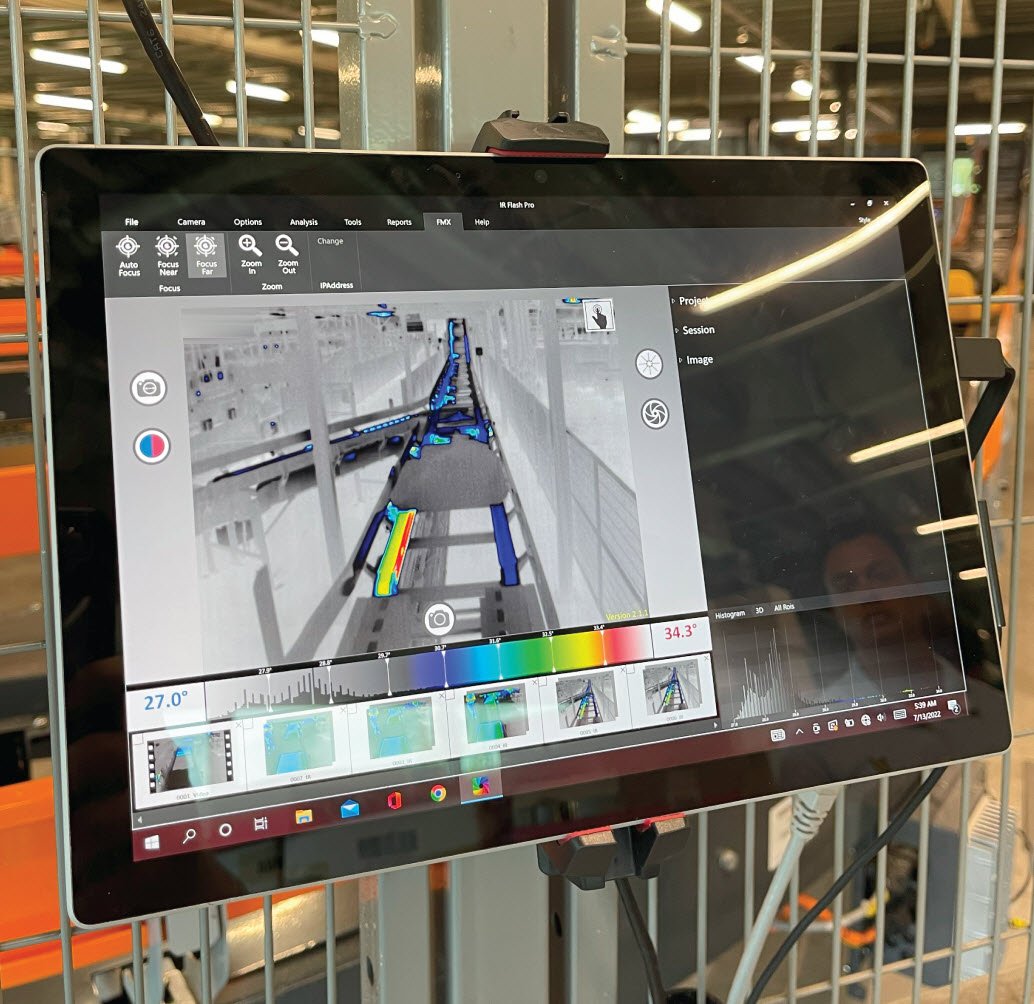

MSAI Connect is an AI-enabled condition monitoring platform designed to prevent asset failures and safety hazards throughout a facility. Powered by Amazon Web Services, MSAI Connect uses remote thermal imaging to identify temperature deviations based on user-set KPIs. Customizable dashboards create at-a-glance visibility into key variables, and real-time alerts instantly notify employees when anomalies are detected, allowing them to proactively address issues before they escalate into larger problems.

Predictive maintenance is a valuable, forward-thinking strategy in modern asset management. Implementing a data-driven maintenance strategy can reduce costs, increase efficiency, and protect the safety of your facility, your employees, and your community. Using AI-powered analytics, thermal sensors, and smart technology can help you anticipate when machinery is likely to malfunction, reducing unplanned downtime and maintenance costs while optimizing equipment performance. Explore our site to learn more about the MSAI platform and how thermal imaging can enhance safety and efficiency.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.