Run to Failure vs. Condition-Based Monitoring: Optimizing Asset Health

If you depend on machinery to keep your operation running smoothly, how you manage your company’s equipment is vitally important. There are two main approaches to maintaining these critical assets: run to failure (RTF) and condition-based monitoring. In this article, we’ll explore the benefits and drawbacks of each approach and discuss how you can optimize the health of your company’s assets.

Run to Failure

RTF is a reactive maintenance strategy. You allow equipment to run until it stops working. This “if it ain’t broke, don’t fix it” strategy can be tempting to adopt because it allows you to keep everything moving as long as possible, avoiding the need to invest in monitoring equipment or interrupt progress with planned downtime. Rather than spending resources on proactive maintenance, you focus that energy on productivity.

RTF, however, can be a risky approach. When you allow equipment to keep running until you encounter a problem, downtime becomes unpredictable, repairs are often more costly, and malfunctioning machinery is more likely to pose safety hazards to employees and perhaps even the larger community. When breakdowns occur, the costs associated with these issues can quickly surpass the time and money you save in the short term.

Condition-Based Monitoring

CBM, on the other hand, is a proactive strategy for asset management. Using sensors and advanced data analytics, businesses can detect issues at their earliest stages, before they escalate into larger problems, significantly disrupt operations, or threaten worker health and safety. When properly implemented, CBM saves time and money while enhancing worker safety.

CBM vs. Preventive Maintenance

CBM is not the old preventive maintenance model. In the past, a proactive approach to equipment maintenance required regularly scheduled maintenance aimed at preventing problems from occurring. Parts were replaced according to manufacturers’ recommendations, no matter their actual condition, to head off issues. While this can reduce risk compared to an RTF model, it tends to both waste resources by fixing nonexistent problems and miss issues that arise between regularly scheduled maintenance tasks. By utilizing sensors and AI-enabled data analysis, managers get real-time insight into the condition of machinery and components, allowing them to target maintenance where it’s needed most without having to wait for problems to surface.

Benefits of Condition-Based Monitoring

CBM offers businesses multiple benefits, including the ability to perform predictive maintenance, extend equipment life, save time and money, and improve safety.

Predictive Maintenance

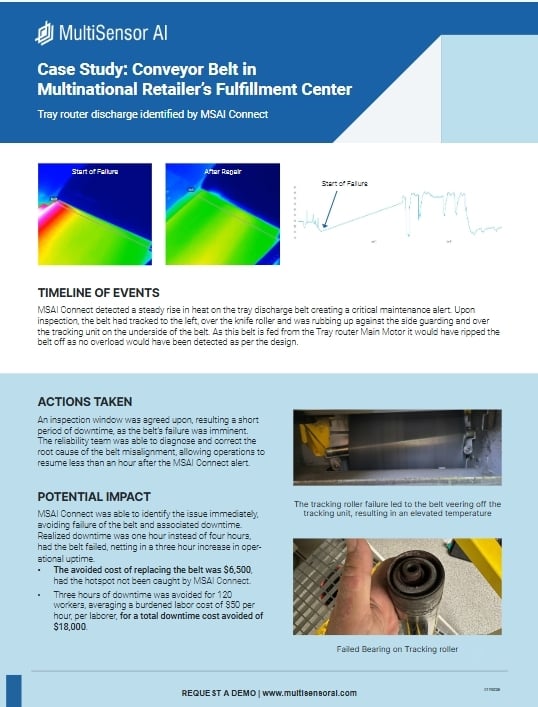

Predictive maintenance is an asset management strategy that uses the power of AI to glean actionable insights from sensor data. Sensors collect data on variables like temperature and vibration, which remain within a certain range during normal operation. Changes in these variables often indicate specific changes in how a machine is operating. Users set key performance indicators for each machine, and the AI analyzes the constant stream of sensor data, allowing key employees to view detailed customized reports via a single pane of glass. Instant notifications can alert decision-makers to anomalies, so they can order appropriate maintenance precisely when and where it’s needed. This allows businesses to save money in multiple ways.

- Catching problems early can prolong equipment life, increasing the ROI of these assets.

- A predictive maintenance program can reduce maintenance costs by eliminating the need for regularly scheduled tasks.

- When maintenance isn’t an emergency, managers can schedule tasks for when downtime will have the least possible impact on the operation.

Customer Satisfaction

When your operation runs smoothly, your business is best able to keep your customers happy and coming back to you. Preventing equipment failure allows you to consistently deliver products on time. Not only does this help your business grow, but it also prevents costs associated with customer dissatisfaction such as refunds, contractual penalties, customer attrition, or even lawsuits.

Workplace Safety

Real-time alerts help ensure that equipment problems don’t slip through the cracks due to improper maintenance practices. Because properly running equipment is less likely to injure workers or cause any kind of environmental or property damage, condition-based monitoring can be an integral part of an overall risk management strategy. Additionally, when you invest in building a safer workplace, you help build a more satisfied workforce. In turn, you can enjoy lower turnover rates and reduce overall hiring costs.

An RTF approach to asset maintenance may save time and money in the short term, but it poses significant risks to profitability as well as workplace safety. Condition-based monitoring allows businesses to avoid unnecessary routine maintenance costs without risking costly and potentially dangerous equipment failures. With continuous monitoring and real-time insights into equipment operation, organizations gain greater control of their critical assets.

MultiSensor AI for Effective CBM Implementation

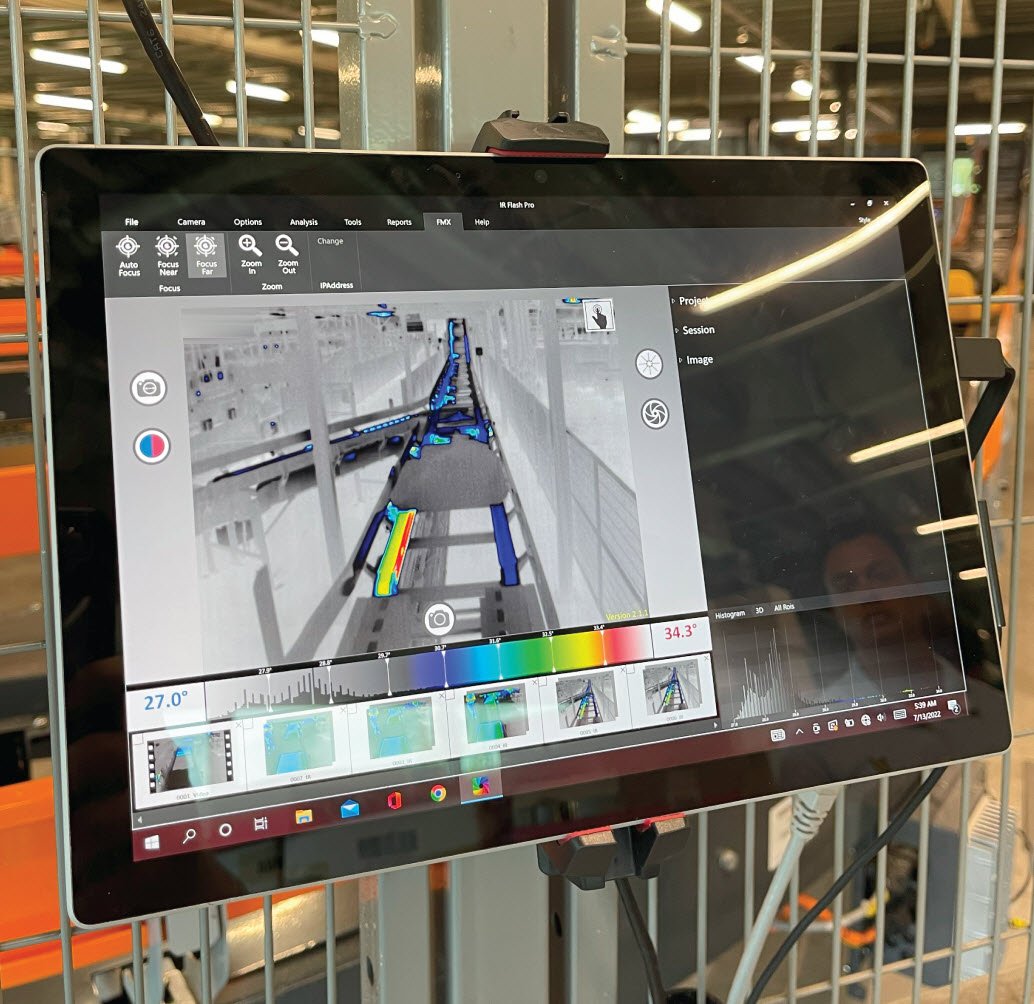

MultiSensor AI (MSAI) is an AI-powered condition monitoring system designed for industrial environments. Easily integrable with common business intelligence systems like EAM, DCS, PLC, and SCADA, MSAI can automatically generate work orders or trigger other responses to anomalies in the system you already use. To provide businesses the security and accessibility features that best support their specific needs, MSAI is available for both cloud and on-premises use.

To learn more about condition-based monitoring, predictive maintenance, and how AI can power more efficient and effective asset management, browse the MSAI blog.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.