How to Reduce Equipment Downtime with Multi-Sensor Condition-Based Monitoring

Register below to access the on-demand recording.

On-Demand Webinar: How to Reduce Equipment Downtime with Multi-Sensor Condition-Based Monitoring

Stop guessing. Detect earlier. Plan maintenance before downtime hits.

In this on-demand session, MultiSensor AI’s team and an Industry 4.0 /predictive maintenance leader walk through a practical, step-by-step approach to moving from reactive maintenance to condition-based monitoring—without creating “dashboard chaos” for technicians.

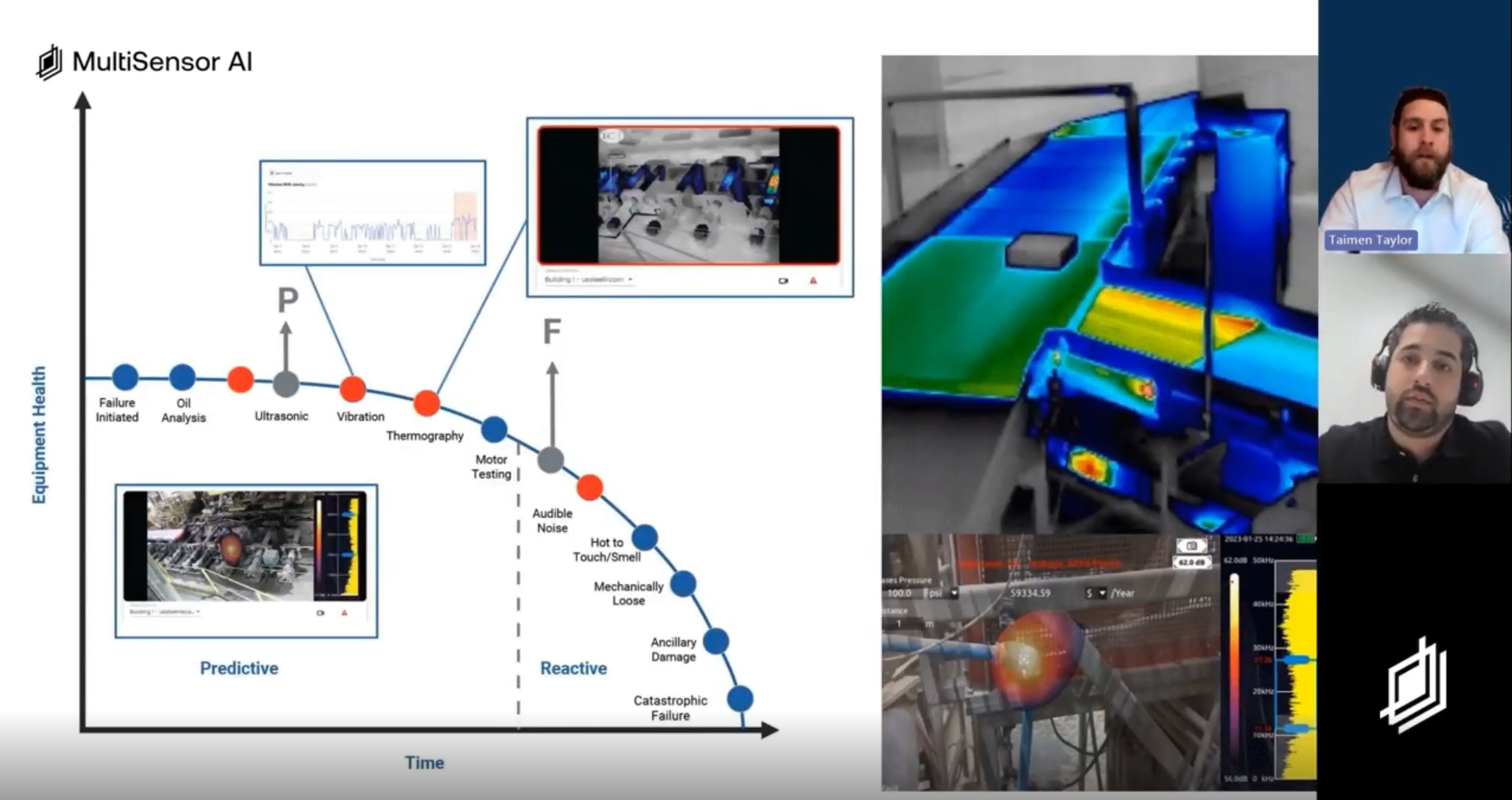

Most industrial teams still operate with a mix of run-to-failure and calendar-based PM—because early signals are fragmented, hard to trust, or too manual to scale. In this webinar, you’ll learn how leading organizations combine multiple sensing methods (thermal, vibration, ultrasound, etc.) to reduce false positives, increase confidence in what’s actually degrading, and integrate insights into existing maintenance workflows. You’ll also hear clear ROI sources (downtime, spares, labor, safety) and how teams build a baseline fast enough to start seeing value in months—not years.

Benefits of Condition-Based Monitoring

- How to choose CBM technologies using the P-F curve (what detects early vs. late—and why it matters)

- Why multi-sensor validation reduces false positives and improves decision confidence

- A practical path from handheld inspections → automation with sensors → scalable analytics

- How to structure ROI: avoided downtime, spare parts optimization, maintenance labor efficiency, and safety exposure

- How much history you actually need to begin: how teams establish baselines in weeks—not months

- Integration strategies so insights land where your team already works (CMMS / dashboards /workflows)—instead of adding another screen

Speakers

Taimen Taylor — Computer Engineering background; 10+years in infrared / remote sensing and condition assessment across industrial environments; MultiSensor AI.

Marouane Lahmidi — Mechanical Engineer; former steel industry maintenance; led predictive maintenance strategy across Amazon (RME); worked on Industry 4.0 and predictive maintenance services at AWS; founder / AWS partner focused on Industry 4.0 solutions.