Making Reliability Actionable.

How multi-sensor monitoring, AI-driven insights, and real-world programs prevent failures before they escalate.

Resources subscription

Featured Resource

From Walkdowns to Continuous Coverage: What Actually Changes

The Misconception About Continuous Monitoring For many buyers, “continuous monitoring” sounds like more technology layered onto an already crowded environment. More alerts. More ...

Blog

From Walkdowns to Continuous Coverage: What Actually Changes

The Misconception About Continuous Monitoring For many buyers, “continuous monitoring” sounds like more technology layered onto an already crowded environment. More alerts. More ...

Why Calendar-Based Inspections Can’t Keep Up With Fast Failure Modes

The Assumption Behind Calendar-Based Inspection Programs Most reliability programs rely on calendar-based inspections for a simple reason: they are predictable, auditable, and ...

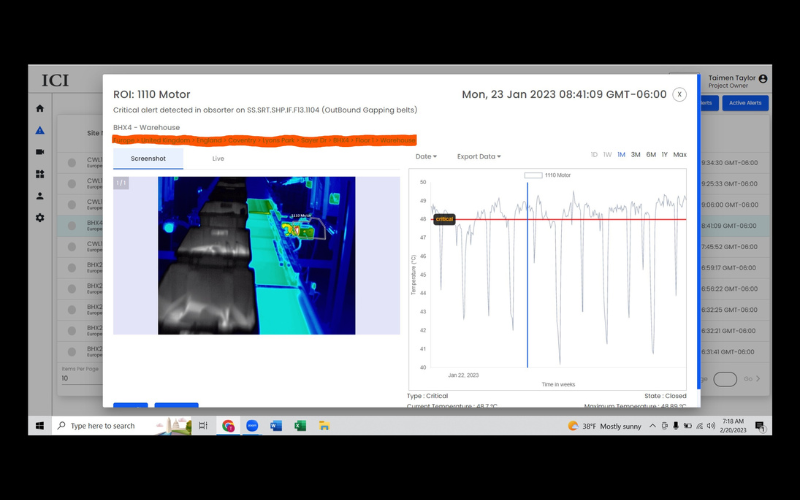

Detection Timing vs. Prediction Accuracy: The KPI No One Tracks

In predictive maintenance conversations, one question shows up almost immediately: “How accurate is it?” Accuracy feels objective. It feels technical. It feels like the right way ...

Why Most Reliability Programs Still See Failures Too Late

Most operations and maintenance leaders believe they have strong reliability programs. Inspections are scheduled. OEM alarms are enabled. Dashboards are populated. KPIS look in ...

Building More Reliable Baggage Operations at Scale - Manchester Airport Group Selects MSAI

MultiSensor AI is excited to announce the planned deployment of its reliability monitoring solutions with Manchester Airport Group (MAG), one of the UK’s leading airport ...

-1.png)

Why UK Operators Are Moving Toward Continuous Condition Monitoring

Across the UK, operators responsible for critical infrastructure are reassessing how they manage reliability, safety, and uptime. Periodic inspections and route-based checks are ...

Gain a Competitive Edge with a Data-Driven Maintenance Strategy

As a business leader, you want to protect your organization from liabilities while optimizing productivity and profitability. Keeping machinery running smoothly, safely, and ...

Prescriptive Maintenance: Next-Gen Asset Management

Proactive equipment maintenance is important for businesses of all kinds, but it’s especially critical in industries like manufacturing, distribution, and electrical power ...

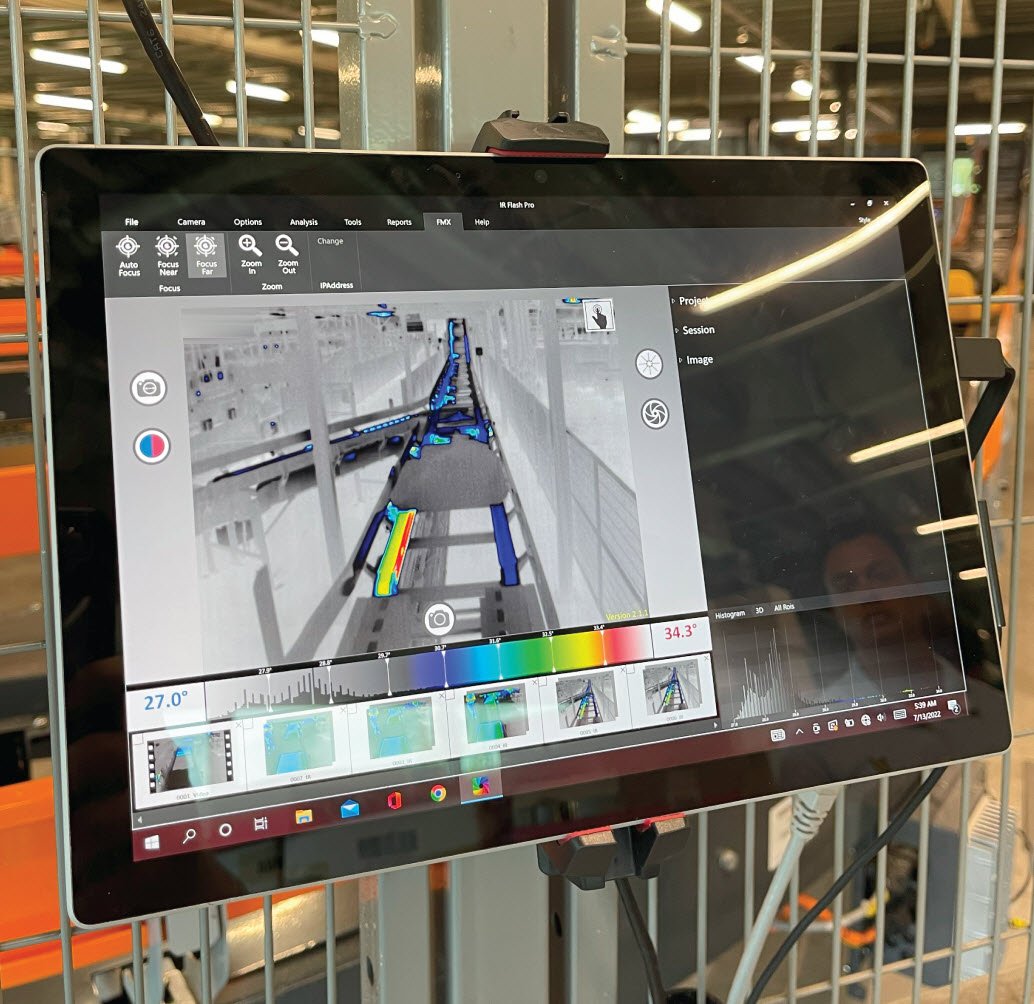

Condition-Based Monitoring for Conveyors Systems

Get a demo

Condition Monitoring for Early Fault Detection

Equipment reliability is a top concern for manufacturers, distributors, utilities, and many other businesses. Failures and unexpected downtime not only impact productivity and ...

Distribution & Logistics Manufacturing MSAI Connect Blog

The Impact of AI on Predictive Maintenance

Businesses are always searching for ways to operate more efficiently, reduce costs, and improve the performance of their assets. In the manufacturing industry, this includes ...

Run to Failure vs. Condition-Based Monitoring: Optimizing Asset Health

If you depend on machinery to keep your operation running smoothly, how you manage your company’s equipment is vitally important. There are two main approaches to maintaining ...

How Data-Driven Predictive Maintenance Affects Employees

Transitioning to a data-driven predictive maintenance program offers numerous benefits. Many business leaders understand that adopting a predictive maintenance model can enhance ...

See the Unseen: Common Issues Detected with Thermal Imaging

The world around us is filled with hidden information, which can often be revealed by temperature variations that are invisible to the naked eye. Thermal imaging technology steps ...