How real-time thermal video monitoring at AWS got faster, cheaper, and more resilient

Disclaimer: This interview was originally aired in September 2023. Infrared Cameras Inc.’s cloud software, referenced in this discussion, is now known as MSAI Connect, part of the MultiSensor AI platform.

When Amazon set out to make its global operations safer, smarter, and more efficient, infrared technology became a key part of the plan. Infrared Cameras Inc. (ICI)—a subsidiary of MultiSensor AI—partnered with Amazon Web Services (AWS) to build a scalable, cloud-based system for 24/7 thermal monitoring.

This collaboration was recently featured in an episode of AWS Innovation Ambassadors, a podcast that highlights groundbreaking customer projects built on AWS. In the interview, Jeff Guida, former Chief Innovation Officer at ICI/MultiSensorAI, and A.B. Madden, Senior Software Engineer at MultiSensor AI, joined Ozan Cihangir, AWS IoT Prototyping Engineer, to discuss how they engineered a solution that dramatically reduced costs, cut latency, and increased resiliency for large-scale thermal monitoring.

You can watch the full episode below:

From infrared cameras to cloud intelligence

Infrared Cameras Inc. has spent decades advancing the science of thermal imaging. What began as handheld inspection tools for trained thermographers has evolved into fixed-mount, continuously streaming cameras that automatically detect abnormal heat signatures around the clock.

As Guida explained in the podcast, “Infrared cameras see heat. They measure temperature for every pixel in their field of view, unlocking a level of insight that’s impossible with the naked eye.”

With costs of infrared technology now 90–95% lower than a decade ago, ICI recognized the opportunity to bring always-on monitoring to industrial and logistics environments worldwide. The company built the Infrared Camera Cloud (since rebranded as MultiSensorAI MSAI Connect software platform) —a first-of-its-kind platform that streams radiometric data from hundreds of cameras to the cloud for real-time visibility, alerting, and analytics.

The challenge: streaming thermal video at scale

As ICI expanded its cloud platform, it discovered that continuous video streaming came with an unexpected hurdle: AWS data egress costs. Each time a customer viewed live video, data flowed through AWS’s Kinesis Video Streams (KVS) pipeline, incurring outbound charges. For a customer managing hundreds of cameras, this quickly became unsustainable.

“We realized that every time someone viewed live thermal video, we’d be charged,” said Guida. “That would discourage customers from using the platform, which defeats the purpose of providing real-time visibility.”

ICI reached out to AWS for guidance. Rather than offering a one-size-fits-all answer, AWS assembled its Prototyping Team to help ICI redesign the architecture for both performance and cost efficiency.

The solution: peer-to-peer video streaming

Working side by side, ICI and AWS engineers replaced the traditional cloud video relay with WebRTC (Web Real-Time Communication), a peer-to-peer streaming protocol.

“WebRTC allows video feeds to go directly from the camera to the viewer, bypassing the cloud and avoiding egress costs entirely,” explained AWS’s Cihangir.

The redesign delivered measurable impact:

-

Zero egress charges during peer-to-peer live streaming sessions.

-

Over 70% reduction in total data egress costs.

-

Latency improvement from ~6 seconds to less than one second.

Madden described the result as “transformative,” noting that near-real-time visibility is critical for applications such as quality assurance on manufacturing lines and early fire detection in remote facilities.

Built-in resilience for real-world environments

Beyond cost and speed, the new system also needed to perform reliably in unpredictable industrial networks. AWS and ICI added automated recovery mechanisms that detect disruptions and automatically restart camera pipelines or user sessions.

“Everything fails all the time,” said Cihangir, echoing Amazon CTO Werner Vogels’ mantra. “The goal is to recover instantly without user intervention.”

Guida emphasized that reliability is just as vital for connected warehouses as it is for remote sites:

“When global logistics customers are monitoring hundreds of conveyor belts, even one offline camera is unacceptable. Resiliency is paramount.”

Real results, real partnership

The collaboration with AWS didn’t stop at prototyping. The optimized system is now being rolled out to production, with AWS account teams supporting deployment and scalability.

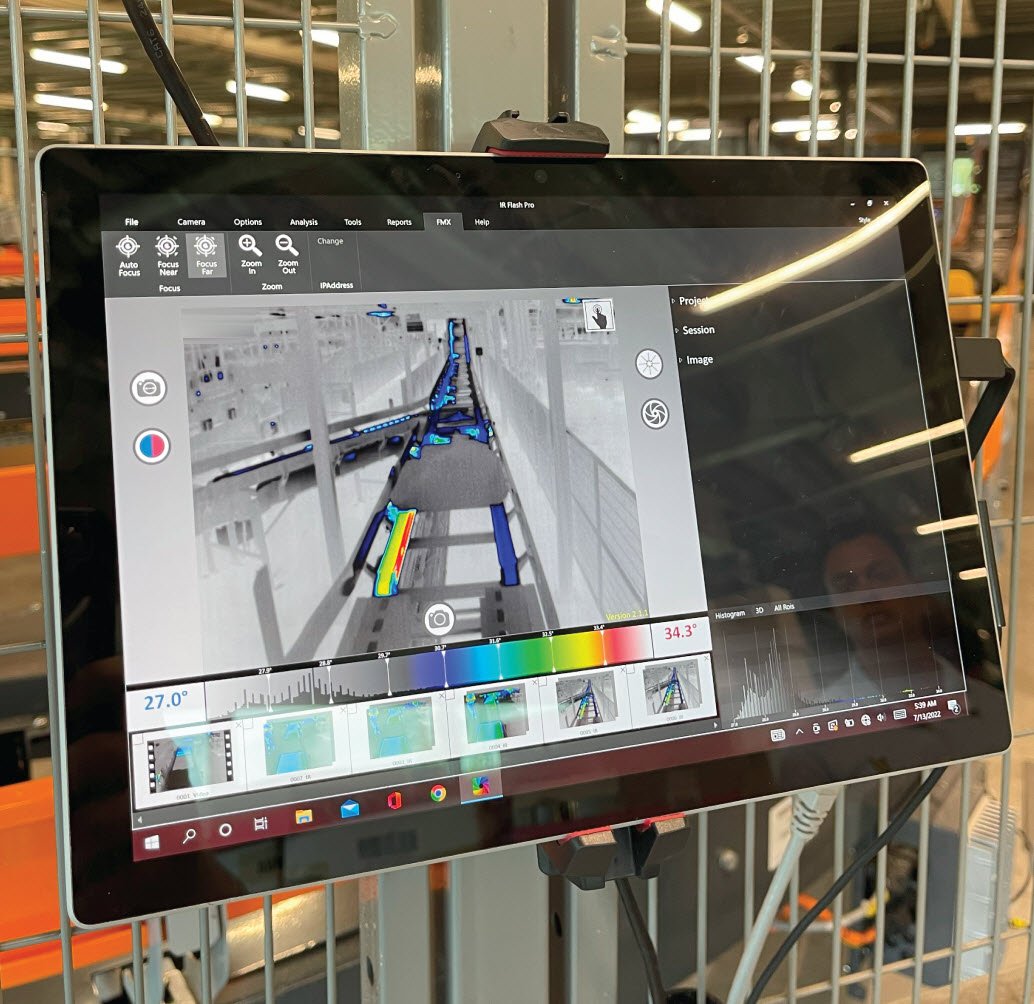

AWS even integrated ICI’s hardware into its Santa Clara Prototyping Lab, where visitors can see the full live demo: an operational conveyor belt, an ICI infrared camera, and cloud-to-edge streaming running in real time.

Guida praised AWS’s approach:

“It’s rare to see a vendor work so hard to help a customer lower their costs. AWS gave us their best and brightest team, and in just six weeks we completely transformed our architecture.”

Why it matters for Amazon and MSAI customers

This case study reflects what MultiSensor AI delivers every day: unified condition-based monitoring that combines advanced sensors, intelligent software, and AI-assisted analysis for safer, more reliable operations.

By integrating ICI’s thermal technology through the MSAI Hub and MSAI Connect platform, industrial customers gain:

-

Continuous visibility across assets and facilities.

-

Early warning for overheating, fire, or mechanical failure.

-

Lower operating costs through efficient data processing.

-

Proven scalability across thousands of connected devices.

For Amazon and other global operators, this means fewer unplanned outages, improved safety, and measurable ROI - often within weeks.

Key outcomes from the AWS–ICI collaboration

-

70%+ cost reduction through peer-to-peer video streaming

-

Latency under one second for live monitoring

-

Automated resiliency for remote and high-volume environments

-

Seamless path to production for scalable deployment

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.