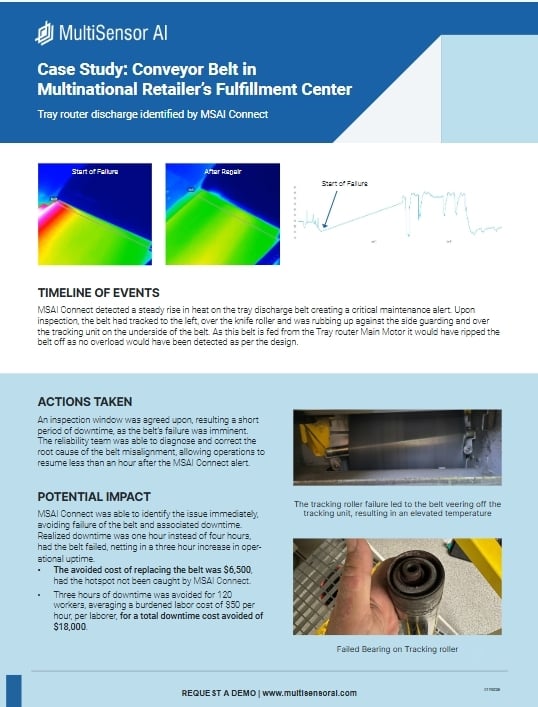

Case Study: Conveyor Belt in Multinational Retailer’s Fulfillment Center Tray router discharge identified by MSAI Connect

This case study shows how MultiSensor AI detected an imminent tray router discharge conveyor failure in a multinational retailer’s fulfillment center. MSAI Connect identified a steady thermal rise caused by a failed tracking roller that forced the belt against side guarding and the tracking unit. The issue was diagnosed and corrected within an agreed inspection window, limiting downtime to one hour instead of a four-hour belt failure. The outcome: three additional hours of operational uptime, $18,000 in avoided labor downtime, and $6,500 in avoided belt replacement costs. A clear example of how continuous thermal monitoring prevents catastrophic conveyor failures before throughput is impacted.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.