Case Study: Conveyor Belt Misalignment in Multinational Retailer’s Fulfillment Center - Belt Misalignment

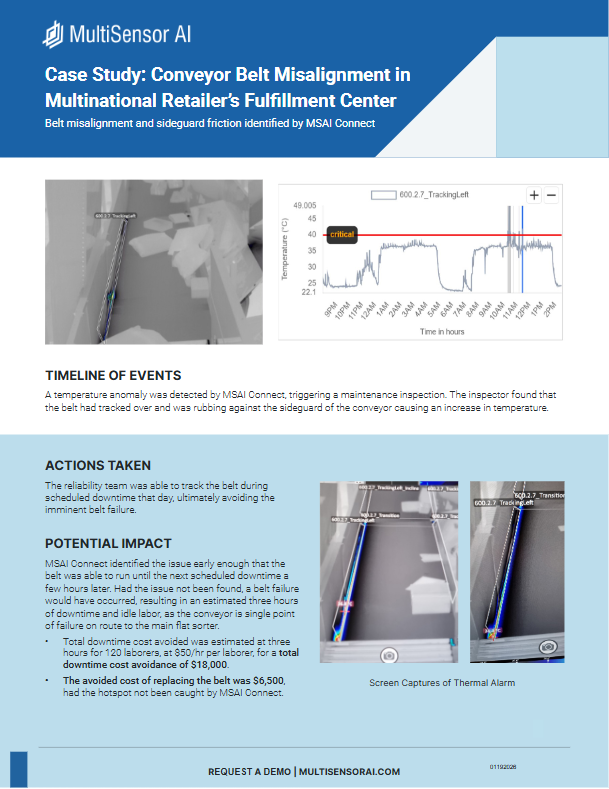

This case study shows how MultiSensor AI identified conveyor belt misalignment and sideguard friction in a multinational retailer’s fulfillment center before it caused a high-severity failure. MSAI Connect detected an abnormal thermal rise as the belt tracked against the sideguard, triggering an early inspection. The issue was corrected during scheduled downtime, avoiding an estimated three hours of unplanned downtime on a single-point-of-failure conveyor. The result: $18,000 in avoided downtime costs, $6,500 in avoided belt replacement, and uninterrupted flow to the main sorter. A strong example of how continuous thermal monitoring protects conveyor reliability and keeps fulfillment moving.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.