Case Study: Conveyor Belt in Multinational Retailer’s Fulfillment Center

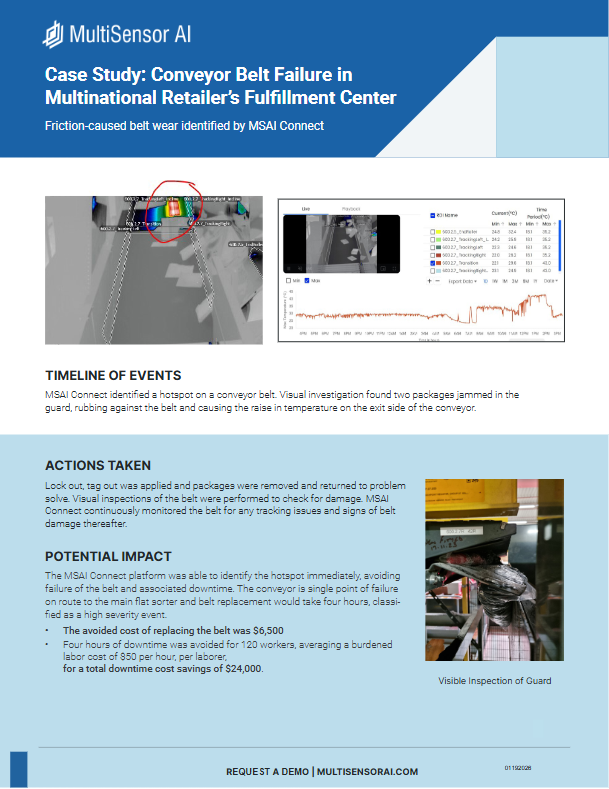

This case study highlights how MultiSensor AI detected friction-caused conveyor belt wear in a multinational retailer’s fulfillment center before it escalated into a high-severity failure. MSAI Connect identified an abnormal thermal hotspot caused by jammed packages rubbing against the belt - enabling teams to intervene immediately. The result: averted belt replacement, avoided four hours of critical downtime on a single point-of-failure conveyor, and more than $30K in combined maintenance and labor cost savings. A clear example of how continuous thermal monitoring protects conveyor uptime and keeps fulfillment operations moving.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.