MSAI Successfully Upgrades Condition Monitoring and Predictive Maintenance Processes in Distribution Center for Fortune 50 Manufacturer

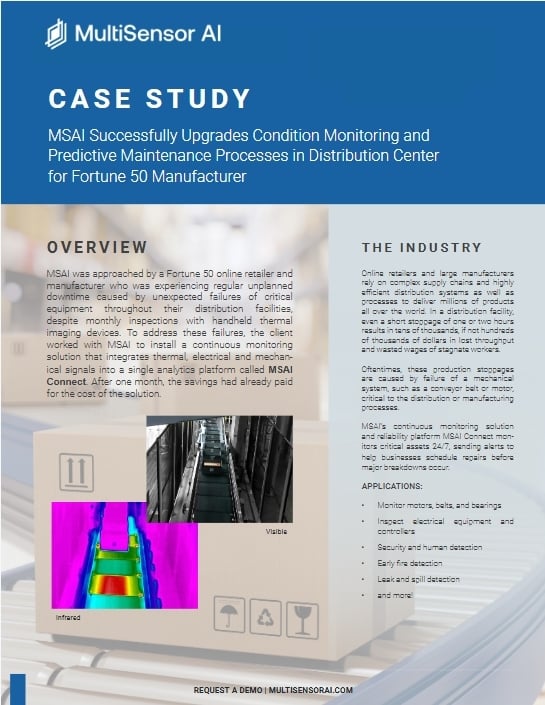

This case study shows how a Fortune 50 online retailer used MultiSensor AI to eliminate recurring unplanned downtime across its distribution facilities. Despite regular handheld inspections, critical conveyors and motors continued to fail. By deploying continuous thermal monitoring with the MSAI Connect platform, the retailer detected overheating belts, misaligned conveyors, and failing motors before breakdowns occurred. The result was immediate cost avoidance across multiple assets, a positive ROI in approximately one month, and a scalable predictive maintenance model now rolling out across global facilities. A clear example of how 24/7 condition monitoring outperforms manual inspections in high-throughput distribution operations.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.