-1.png)

Why UK Operators Are Moving Toward Continuous Condition Monitoring

Across the UK, operators responsible for critical infrastructure are reassessing how they manage reliability, safety, and uptime. Periodic inspections and route-based checks are no longer enough for environments where assets run continuously, and the cost of missed issues is high.

Following multiple successful monitoring programs across Europe and the UK, many teams are introducing continuous condition monitoring to gain better visibility into asset health and reduce the risk of unplanned failures.

This shift is not about replacing maintenance teams or processes. It is about giving engineers earlier, more consistent insight into how equipment is behaving during live operations.

Where do periodic inspections fall short?

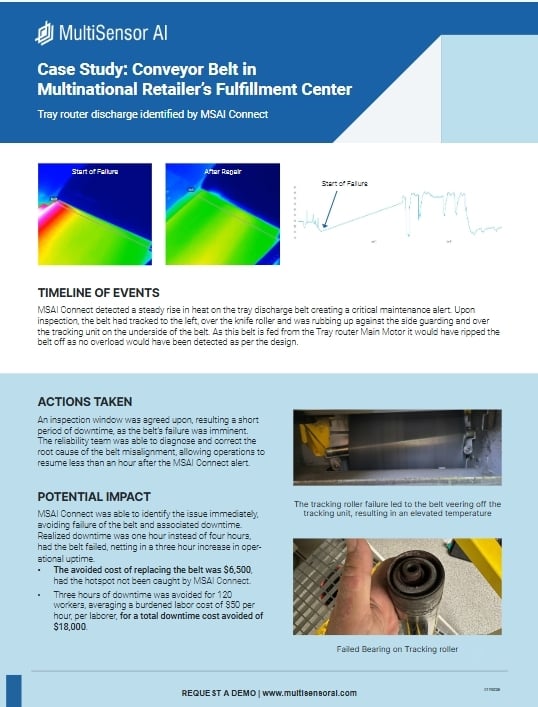

In environments such as airports, automated food production facilities, and high-throughput logistics operations, equipment often operates under sustained load for long periods. Issues like overheating, misalignment, electrical degradation, or bearing wear can develop between inspection intervals.

By the time a problem is visible during a scheduled check, it may already be close to failure. For maintenance teams, this creates a reactive cycle: responding to incidents instead of preventing them.

As a result, operators across Material Handling, Food & Beverage, and Distribution & Warehousing environments are seeking ways to continuously monitor critical assets without adding operational burden.

How to introduce continuous monitoring

UK operators are not making sweeping changes all at once. Instead, they are introducing continuous monitoring in targeted, practical ways that fit existing maintenance workflows.

Monitoring is often first applied in areas where the impact of failure is highest - such as baggage handling systems, production bottlenecks, or critical electrical assets. These early deployments allow teams to assess the quality of insights, understand alert behavior, and refine response processes using real operational data.

As teams see issues detected between inspection cycles, monitoring is extended to additional assets where uptime, safety, or compliance are most critical. Over time, this changes how maintenance decisions are made - shifting from fixed schedules to decisions based on actual asset condition.

This approach aligns with established condition-based maintenance practices used by reliability teams to prioritize work based on risk and asset behavior.

What continuous monitoring enables in practice

Continuous condition monitoring provides a consistent view of asset behavior during normal operations, peak demand, and off-hours - not just during inspections.

By combining fixed monitoring with handheld inspections where appropriate, teams can:

- Identify early signs of overheating or degradation

- Detect issues that develop outside inspection windows

- Prioritize maintenance work based on real conditions

- Reduce the likelihood of unplanned downtime

In safety-critical or highly regulated environments, this approach to early threat detection also supports earlier intervention and improved operational resilience.

How to support reliability without adding complexity

One reason continuous monitoring is gaining traction is that it does not require a wholesale change in how maintenance teams work. Monitoring data can be reviewed alongside existing systems and workflows, providing additional context rather than replacing established processes.

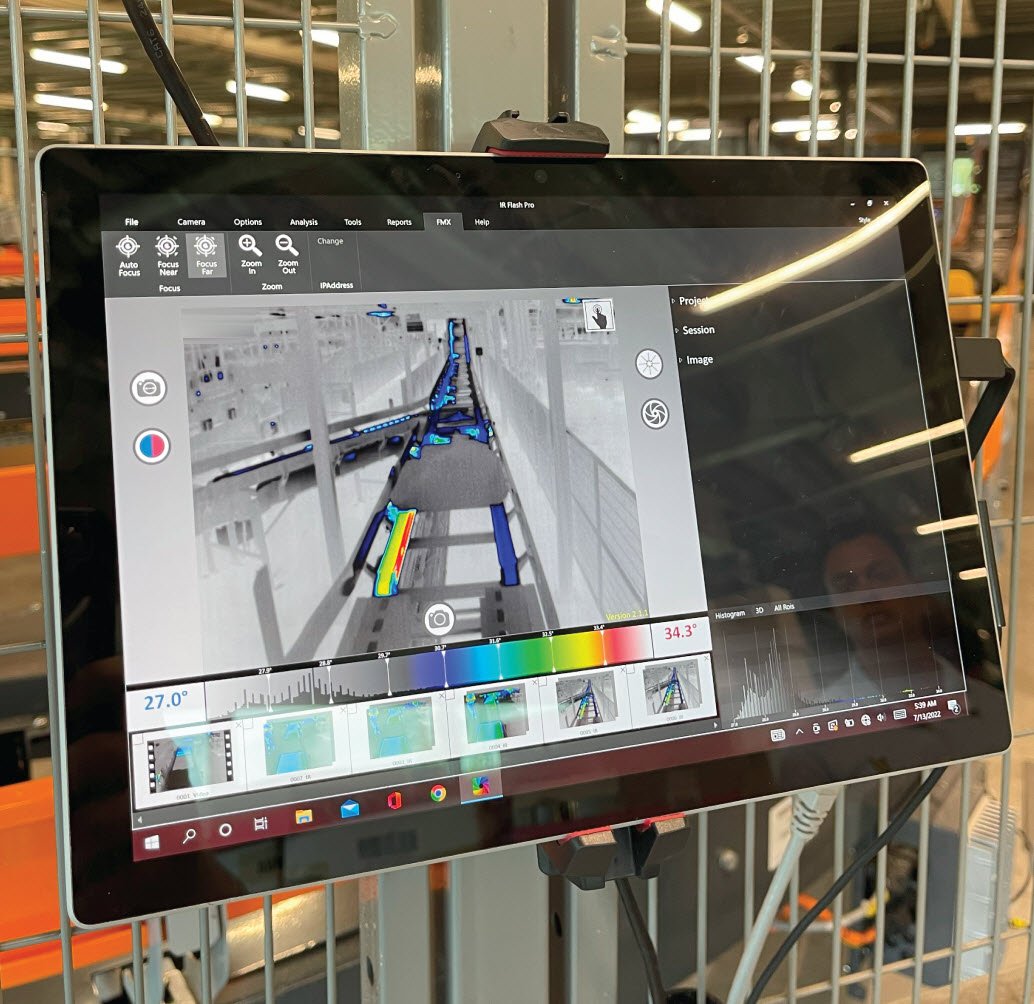

Software platforms such as MSAI Connect aggregate data from multiple sensors to provide a clear view of asset condition, while edge devices like the MSAI Hub support reliable data collection in industrial environments.

Why this shift is accelerating in the UK

UK operators are balancing several pressures at once: aging assets, higher utilization, labor constraints, and increased scrutiny around uptime and safety. At the same time, infrastructure modernization and automation are raising expectations for reliability.

Industries such as Airports, Data Centers, and Supply Chain & Logistics are leading this shift, where standardized assets and continuous operations make condition-based monitoring particularly effective.

The UK is following a path already proven across Europe and North America: introduce monitoring where it matters most, build confidence in the data, and extend coverage as operational value becomes clear.

Looking ahead

As more teams move from periodic inspections to continuous visibility, condition monitoring is becoming a standard part of modern reliability programs in the UK.

For organizations evaluating how to reduce unplanned downtime, improve safety, and support maintenance teams with better information, continuous monitoring offers a practical next step.

Turn early signals into uptime.

Book a working session with one of our condition-based monitoring experts, and we’ll review your assets, assess your maintenance maturity, and show how multi-sensor monitoring catches issues hours, days, or weeks earlier than manual rounds - giving you a clear path to fast, measurable ROI.